She had used a strategy that was not only economically viable, but also generated a lot of employment.

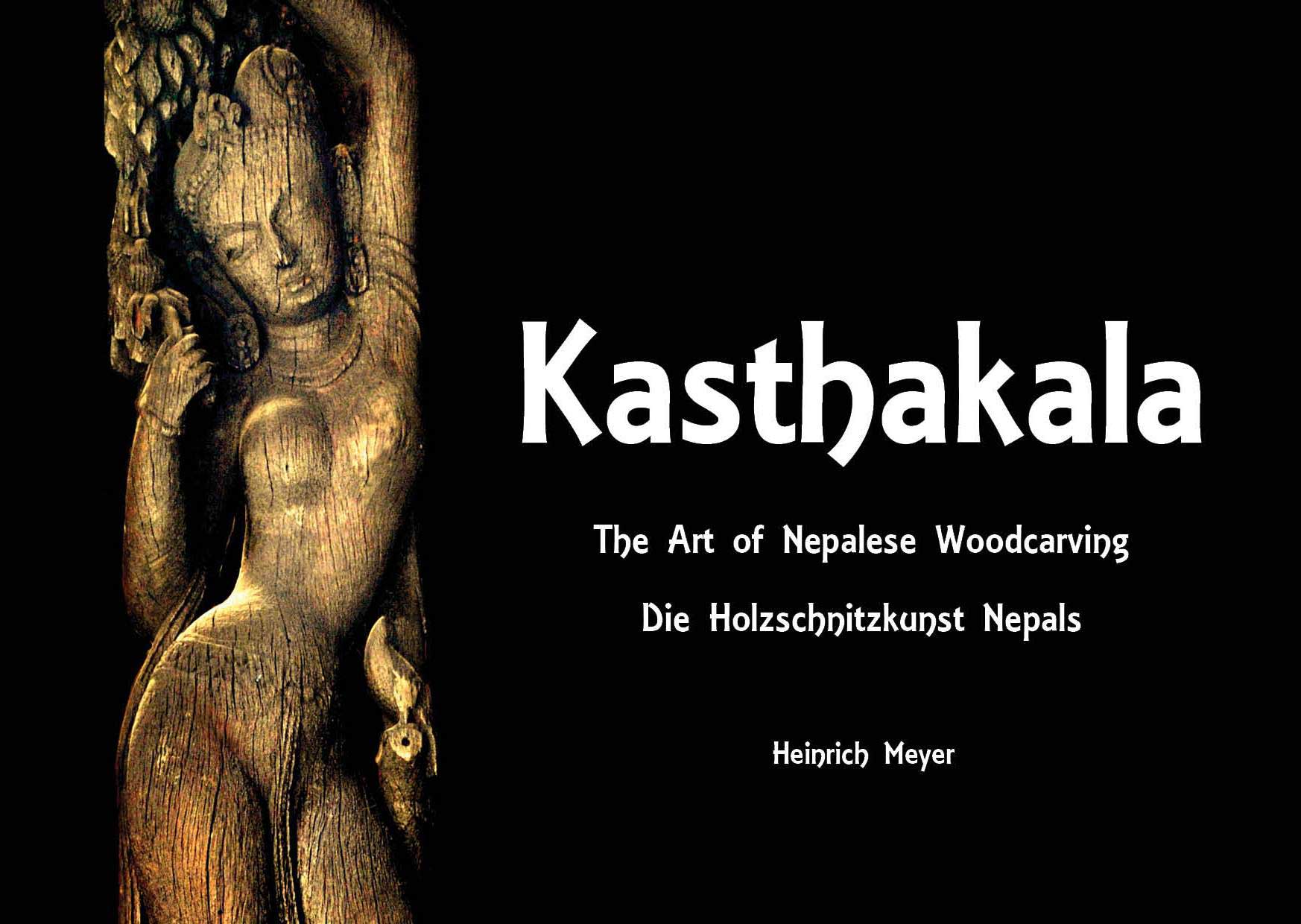

It all started on one fine Friday evening at the Siddhartha Art Gallery, Babar Mahal. The sun was bidding farewell to the sky by coloring the clouds and gently welcoming the darkness of the night. I was there to witness an exhibition on “Contemporary Nepal Basketry” by Shyam Badan Shrestha, chairperson of the Nepal Knotcraft Center (NKC). The exhibition had 33 baskets made from raw materials such as sisal fiber, bamboo, banana fiber, pine needles, papyrus, moonj, pater, and water hyacinth. They came in from all over the country, from places like Dang, Dhankuta, Sindhuli, Banke, Bhaktapur, Lalitpur, and Kathmandu. But I was expecting that, it was an exhibition after all. What surprised me was the chairperson herself. When I heard the name “Shyam” I thought it was a guy, but to my surprise it was a lady. She had a sturdy personality, her eyes full of passion, and she spoke of her baskets like she was talking about her children.

I collected a lot of visiting cards that day, but the number I wanted was that of Shyam. I finally met her and asked for her card, but she apologized for not having one. The gallery was full of razzmatazz, and she was the only person who reminded me of my roots. It was the moment that I realized I had to meet her again and have a good conversation with her.

I collected a lot of visiting cards that day, but the number I wanted was that of Shyam. I finally met her and asked for her card, but she apologized for not having one. The gallery was full of razzmatazz, and she was the only person who reminded me of my roots. It was the moment that I realized I had to meet her again and have a good conversation with her.

Shyam had begun work on weaving fibers since 1984; however, it was after the blockade by India in 1989 that she started looking for raw materials found within the country. But, everyone present in the exhibition knew that part of her life, as she herself had said it in her five-minute speech at the event. I wanted to know more about her work, so the next morning I gave her a call. We decided to meet at the Patan Industrial Estate the very next day. I wanted to get a closer look at how the fiber was woven and the beautiful objects created.

I entered the Patan Industrial Estate in search of firm number 93, and after looking for a few minutes, I finally found it. Shyam was waiting for me with her ever infectious smile. She told me to wait in the living room, which was full of materials made of different fibers. Everything from the flooring, the doormat, and the decorations were hand woven. I didn’t feel lonely at all in the company of the families of dolls. They reminded me of my neighborhood, as every box set included a family of a different ethnic group. It took me sometime to realize that the sofa I was sitting on was also made from bamboo.

.jpg) She arrived after a few minutes, and we started talking. When she had begun her career, she imported the thread from India; at the end of 1989, there was a trade blockade by India, and for 13 months there was no thread. It was then that she started looking for raw materials made in Nepal. “We started with dolls made of corn musk, then the dokos, dallos, kharpans for the dolls. Next, we started making baskets from bamboo, which were bought by many restaurants. It required not only skills, but also a lot of patience. Two boys from Dhankuta were the first workers I hired,” she said. She enjoyed the art of creating baskets from fibers, and transforming them into bread baskets of top restaurants and hotels.

She arrived after a few minutes, and we started talking. When she had begun her career, she imported the thread from India; at the end of 1989, there was a trade blockade by India, and for 13 months there was no thread. It was then that she started looking for raw materials made in Nepal. “We started with dolls made of corn musk, then the dokos, dallos, kharpans for the dolls. Next, we started making baskets from bamboo, which were bought by many restaurants. It required not only skills, but also a lot of patience. Two boys from Dhankuta were the first workers I hired,” she said. She enjoyed the art of creating baskets from fibers, and transforming them into bread baskets of top restaurants and hotels.

As I was surrounded by countless work of hand-woven magic, I asked her about any piece of work that she had fond memories of. She went to the closet and brought out a basket. A classic example of Tharu artistry made up of kaas and moonj. “It takes a week to make this one basket, which is called delwa. This is a cultural product of the Tharus. If a Tharu woman can’t weave this during the time of her marriage, she cannot get married,” she said. She put the basket on her head and tried to imitate a Tharu woman’s walk, which brought a smile to my face.

It was surprising to know that it had been 15 years since the basket was made, but it remained unsold. The beauty of that basket made me feel that she could have an exhibition of unsold baskets.

.jpg)

The fascinating thing about Shyam was that she often named the product after the name of the workers who made them. For instance, Pushpa baskets, Gurkhi stitch, Hem ghera (circle), and so on. Shyam is very close to her employees. She told me about one girl who came to her looking for a job when she was in high school. She later completed her masters, got married, and is now the finance manager of the company. “We had 85 women workers in 2010, among them 36 were working in the factory, but later we had to close down in the same year and opened as a private company,” said Shyam.

Shyam Badan Shrestha is very careful while choosing the raw materials. “Raw materials’ strength and durability is something we study and experiment upon. We have discovered 45 plant fibers in Nepal,” she said. She believed that it was important to know the right type of raw materials to be used in the various weaving techniques.

.jpg)

She talked about various weaving techniques in use that were given local names. There is the Kathmandu weaving used in the capital, the twine weaving, the fish bone weaving, which was quite popular among the people in Terai, simple weaving, gundri weaving, and Sang tang weaving, used commonly by the Rai community. She emphasized on traditional weaves, as they strengthen the objects, and when the stitches are visible on the outside, it adds new design to the product and makes the work go faster. She has great admiration for the women of the Terai. She is amazed by the fast hands and supreme skill they possess. They make one craft in one day and sell them in the haat bazaar.

She has done a lot for women empowerment as a whole. She remembers one woman in the Terai telling the story of how her life changed after she started working. Her husband washed the clothes so that she could work, and her daughter, who studied in class eight, cooked the meals so that she could work in peace. “When a woman starts earning, she gets the love and respect that she deserves,” she said. “Ninety-nine percent of our employees are women, excluding the driver and the watchman,” she further added with a chuckle.

I asked her about her upbringing, and she closed her eyes as if she had been transported back in time. “In the earthquake of B.S. 1990, our house was partially damaged. It happened before I was born, but growing up in a broken house, I constantly lived in fear. So, all I thought was that I had to survive, to survive I had to work, and to work I needed to get myself educated,” said Shyam

I asked her about her upbringing, and she closed her eyes as if she had been transported back in time. “In the earthquake of B.S. 1990, our house was partially damaged. It happened before I was born, but growing up in a broken house, I constantly lived in fear. So, all I thought was that I had to survive, to survive I had to work, and to work I needed to get myself educated,” said Shyam

Shyam has done a lot for women entrepreneurship. She led the project, entrepreneurship development for tourism, in collaboration with Women Entrepreneurs Association of Nepal (WEAN), Annapurna Conservation Area Project (ACAP), and Ama Samuha in seven-eight districts. She was the founding member of Women’s Entrepreneurs’ Association Nepal, and a past president, as well. During that time, she traveled all over the country to motivate women to take up entrepreneurship.

Shyam has big plans for the future. She wants to open a mobile craft school in the future, and introduce weaving in the education sector. She feels people don’t give respect to artists in this field. She is also worried that the lack of knowledge regarding plants is adversely affecting the fiber weaving industry. She gave the example of how the elaichi (cardamom) plant’s roots and branches that make 80 % of the plant, can be used for weaving, but people only take the elaichi, while the rest of the plant is wasted.

She is not new to interviews. I wasn’t the first person to come to her with questions. A long time ago, Nepal Television interviewed her. The channel had also broadcast the process of how the beautiful products were woven. She believes a lot of people learnt the art of weaving by watching the broadcast. “My elder daughter, Subrina Shrestha, works for Aljazeera. I wish she did a story on me,” she said with a smile.

The hand-woven goods not only have a good hold in the domestic market, but are equally popular internationally. They are exported to countries like Norway, Japan, Germany, and the U.S.A., which Shyam considers as a very strong market for handicrafts.

But it wasn’t always so. Constant political interferences have significantly impacted the company and its workers. The Maoist insurgency had affected her work severely. She recalls a horrific incident when she was dragged out of her house by a Maoist combatant. She says trade unions also have been a constant threat to the production of the hand-woven goods. She had to close it in 2010, and open as a private company a few years later.

With determined eyes, she put her fist in the air: “When you are an entrepreneur, you don’t stop because there is a problem. You carry on and find a solution. We largely owe our thanks to the women shareholders because of whom we got back on our feet,” she said.

She had used a strategy that was not only economically viable, but also generated a lot of employment. Even though she had no workers in the factory, she had many working for her all over the country. Women kept on working despite swollen thumbs and sore fingers. They had the desire, the hunger, and the drive to run their houses. The same attributes that one could see in Shyam’s eyes. Following her small footsteps, they had taken giant strides.