Winter’s quite something else. Granted it gets you lazy and fat and as the days become shorter, it also brings the couch potato side of you out of hibernation. But winter is also the season when food tastes better, sleeping feels blissful, and everyone looks forward to long evenings in front of a warm fire sharing the day’s tales. It is also the time the year when your jackets and your woolens come out of the closet. For me there’s nothing that spells out winter better than the memory of my mother sitting in front of the television, a ball of colorful yarn at her feet, knitting a cuddly, white and yellow cardigan for a seven year old me. And today, everywhere I look on the streets of Thamel, there are bright, multicolored, handmade woolen cardigans and woolen caps for sale, reminding me of my childhood passion for that sweater. When I started out to learn a little more about clothing for chilly weather, I had that comforting image in my mind.

The Lhasa Connection

Time and again, the stories we cover allow us to appreciate just how important Nepal’s Lhasa Newars trading in Tibet have been for our economy, traditions and culture. Visiting the Nepali woolen showrooms in Thamel helped me appreciate how and where some of that history got started. Luckily for me, the woolen shop I arbitrarily chose as a starting point for my research turned out to be owned by a descendant of a prominent Lhasa Newar woollen trader. The storekeeper, Chandra Tuladhar, was a little apprehensive at first about what I wanted to know, but he warmed up once we start talking about those earlier days and his family’s history.

“My grandfather was one of the popular Lhasa Newars who facilitated trade of various items from Nepal in Tibet. He had a shop in Lhasa until 20 years ago, and connections in Nepal. He brought in wool and other items in exchange for cloth, leather, sugar, tobacco and watches from Lhasa. The amount of wool that the Lhasa Newars imported was quite adequate for the Nepal market then, since exports were quite few and far between,” says Chandra. His father, Gyan Bir Singh Tuladhar, started assisting his own father at the age of 12 and eventually took over the business. The family now has a factory in Banepa, 40 minutes drive from Kathmandu, where all the products on display at Chandra’s shop are knitted by dozens of local workers. “Besides boosting the economy by bringing in foreign currency from exports, woolen factories like ours have also provided employment to a large number of locals. Most of our workers are Newars who seem to have a natural aptitude for knitting,” Chandra notes. Factories like these provide employment to the elderly, to youth, and to unemployed housewives whose husbands are mostly occupied in small businesses or farming. Many such factories are located in Banepa, and have had a huge role in boosting the area’s living standard.

The Tuladhar family also once had a shop in Jhochhen, more popularly known as ‘Freak Street’. In the shop’s heyday about 32 years ago Nepal was a haven for hippies, and Jhochhen,because of its inexpensive lodges,colorful personalities and easily available drugs, was the place for hippies and wannabe hippies to hang out. The Tuladhars’ woolen business thrived during that period and after 12 years, as the hippies started to leave and the tourist district moved over to Thamel, so too did the store. The present store,simply called Tuladhar Store, is run by the friendly Chandra Tuladhar. “We are wholesalers and have been in the business for more than three decades. During this time, many shops have been opened and closed down. The wool business like many other trades depends heavily on trust and good repute, both of which we have earned over the years,” says Tuladhar, with the beginnings of a smile.

When I ask Chandra about business, I half expected the usual answer of how the country’s political strife has taken things from bad to worse. But I was taken aback by Chandra’s huge smile as he informed me of a growing market in continental Europe for woolen goods made in Nepal. “America and England, too, are potentially huge markets for woolen products from Nepal, but our major buyers are from mainland Europe,” says Chandra. He add“Businessmen from Europe, and even some tourists, buy huge amounts of yak and sheep wool products from stores here in Thamel. Businessmen place their orders in the spring, as it takes about two to three months for us to produce such large quantities. Then, by winter, our products are available in stores all over Europe. Our woolen products—

because of their unique structure and designs—are exclusive,” says Chandra.

Chandra also informed me that popular items such as woolen cardigans and caps sell for at least five times higher on the foreign market than when they are bought here. Yak wool is very popular, due to its unique texture and all the mythology that surrounds these animals that are found only in the high mountains of Nepal and Tibet. Yak is considered the best, as it consists of stronger and softer yarn as compared to other wools. Clothing made of this high quality wool has a longer life than what is made of lesser quality wool. One problem, however, is that yak wool lacks the color of pure white. It also does not respond as well to dyeing as sheep wool does. Therefore, most woolen products are knitted by hand combining both sheep and yak wool to obtain a staggering number of amazing, colorful designs. Given its strength and hardiness, yak wool is also well suited to making Tibetan carpets, which are popular on the American market.

The last two to three years have seen the introduction of machinery in the woolen factories, but hand made products are still more popular and also more durable. In the serene city of Kirtipur, one of the older places where woolens are still made by hand, we came across Bajracharya families that were happily knitting away in the midday sun. Groups of women, mostly housewives, get together in courtyards after lunch and chat away as they knit woolen sweaters and caps till the sun sets. Wearing colorful saris and sitting cross legged with colorful balls of wool at their feet, their jolly laughter echoes through the sunny alleys of the old city.

In Banepa, where the Tuladhars’ factory is located, all the products are handmade. The wool that is used here is brought in from Tibet and India, then it is processed into the fine balls of yarn that are used to knit cozy woolen clothes and accessories.

Using this wool, Chandra and other manufacturers like him produce an overwhelming number of woolen products: pullovers, jackets, caps, earmuffs, mufflers, slippers, scarves, blankets, socks, ponchos, and gloves. Despite being exclusively handmade and very practical for Nepal’s winters, these products are available at surprisingly low prices. A woolen pullover with fleece costs about NRs 800 and a woolen blanket costs only NRs 400. Other items such as caps, gloves, scarves and mufflers cost less than NRs 100! Talk about great pricing and affordability!

The History of Wool

In 1377 England’s King Edward III—‘the royal wool merchant’—stopped woven-goods imports and the domestic weaving of foreign wools. He wanted only local weaving using domestic wool. Then he invited Flemish weavers fleeing the Spanish invasion to settle in England. The industry thrived, and by 1660 wool textile exports made up two-thirds of England’s foreign commerce. Although pelts may have been worn in Britain as early as the late Bronze Age (3000 BC), England’s ‘empire of wool’ peaked during the the reign of King Henry VIII (1509-47). But when King Henry seized the flocks of the monasteries and redistributed them to court favorites, many unemployed shepherds fell into debt and were sent to prison. This was one of the unfair treatments that encouraged immigration to America. Despite the fact that England also tried to discourage a wool industry in North America, by 1665 a few smuggled sheep had multiplied to nearly a million, and the industry grew enough so that the Massachusetts colony passed a law requiring young people to spin and weave!

Traditions and folklore grew with the industry. Spinning duties fell to the

eldest unmarried daughter in the family; hence the term ‘spinster’. Spun yarn was wound on a reel (weasel) which made a popping sound when a given yardage was reached; hence, ‘Pop goes the weasel!’ England’s King George III made wool trading in the colonies a punishable offense, for which cutting off the offender’s right hand was the punishment. This policy, together with other oppressive measures (such as the Stamp Act of 1765, which required that revenue stamps be affixed to all printed matter and official documents in the colonies), helped incite America’s Revolutionary War. Despite the King’s attempts to disrupt wool commerce, the wool industry flourished in America. Sheep moved west across the continent and to other colonies, so that by the turn of the 18th century small flocks owned by pioneers became the start of the wool industries of Australia, New Zealand and South Africa, as well.

From Wool to Woolens

Wool is the fiber derived from the fur of animals of the Caprinae family, principally sheep, but the hair of certain other species of other mammals such as yaks, goats, llamas and rabbits may also be spun. In Nepal however, most woolen products are made from yak wool or a mixture of yak and sheep wool, which is most available within the country. Wool has two qualities that distinguish it from hair or fur. For one, it has scales that overlap like shingles on a roof, and it is crimped. In some fleeces the wool fibers have more than 20 bends per inch. And, wool is a renewable resource; after shearing it grows back.

Wool straight off a sheep contains a high level of grease with its valuable lanolin, as well as dirt, dead skin, sweat residue, and vegetable matter. This state is known as ‘grease wool’ or ‘wool in the grease’. Before the wool can be used for commercial purposes it must be scoured, or cleaned. Scouring may be as simple as a bath in warm water, or a complicated industrial process using detergent and alkali. In commercial wool, vegetable matter is often removed by the process known as chemical carbonization. In less processed wools, vegetable matter may be removed by hand, leaving some of the lanolin intact through the use of gentle detergents. This semi-grease wool can be worked into yarn and knitted into water-resistant mittens or sweaters. Lanolin removed from wool is widely used in the cosmetics industry, such as hand creams.

After shearing, the wool is separated into five main categories: fleece (which makes up the vast bulk), pieces, bellies, crutching, and locks. The latter four are packaged and sold separately. The quality of fleece is determined by a technique known as wool classing, whereby a qualified wool classer tries to group wools of similar grade together to maximize the return for the farmer or sheep owner. The quality of wool is determined by the following factors: fiber fineness, length, scale structure, color, cleanliness, and freedom from damage. Merino wool, for example, is typically 3-5 inches in length and very fine (between 12-24 microns), while wool taken from sheep produced for meat is typically coarser with fibers only 1.5 to 6 inches in length. Damage or ‘breaks in the wool’ can occur if the sheep is stressed while it is growing its fleece. Stress causes thin spots where the fleece is likely to break.

Present Status of the Wool Trade

Global wool production is approximately 1.3 million tons per year, of which 60% goes into apparel. Australia, China and New Zealand are the world’s leading commercial grade producers of wool. Due to their high prices, however, very little wool is imported to Nepal from these countries. Most Australian wool comes from the Merino breed. Breeds such as Lincoln and Romney produce coarser fibers and wool from these sheep is usually used for making carpets. The American states of Texas, New Mexico and Colorado also have large commercial sheep flocks. Some small farmers maintain a thriving ‘home flock’ tradition, raising small hobby flocks of specialty sheep for the hand spinning market. These small farmers may raise any type of sheep they wish, so the selection of fleeces is quite wide. The woolens available on the Nepal market, however, are mostly from the high altitude sheep and yaks of Nepal and Tibet. Because wool production here is not nearly enough to meet the rising demands of the local and export market, Nepalese business people also buy wool from India.

Uses of Wool

In addition to clothing, wool has been used for blankets, horse rugs, saddle blankets, carpeting, felt, wool insulation, and upholstery. Wool felt is used to pad piano hammers and is also used to absorb odors and noise in heavy machinery and stereo speakers. The ancient Greeks lined their battle helmets with felt, and Roman legionnaires used breastplates made of felted wool. In Nepal, highland ethnic groups such as the Gurungs living on the south flanks of the Annapurna, raise large flocks of sheep and make water repellant woolen capes with stripes, and durable heavy blankets with check designs. Some street peddlars around Kathmandu sell blankets of this sort from the hills.

Wool has also been traditionally used to cover cloth diapers. Since wool fiber exteriors are hydrophobic (repel water) and their interior are hydroscopic (attracts water), wool used in baby diapers inhibits ‘wicking’ so that the outer part remains dry. The natural lanolin in woolen garments makes them water resistant, air permeable, and slightly antibacterial, so that they resist the buildup of odor.

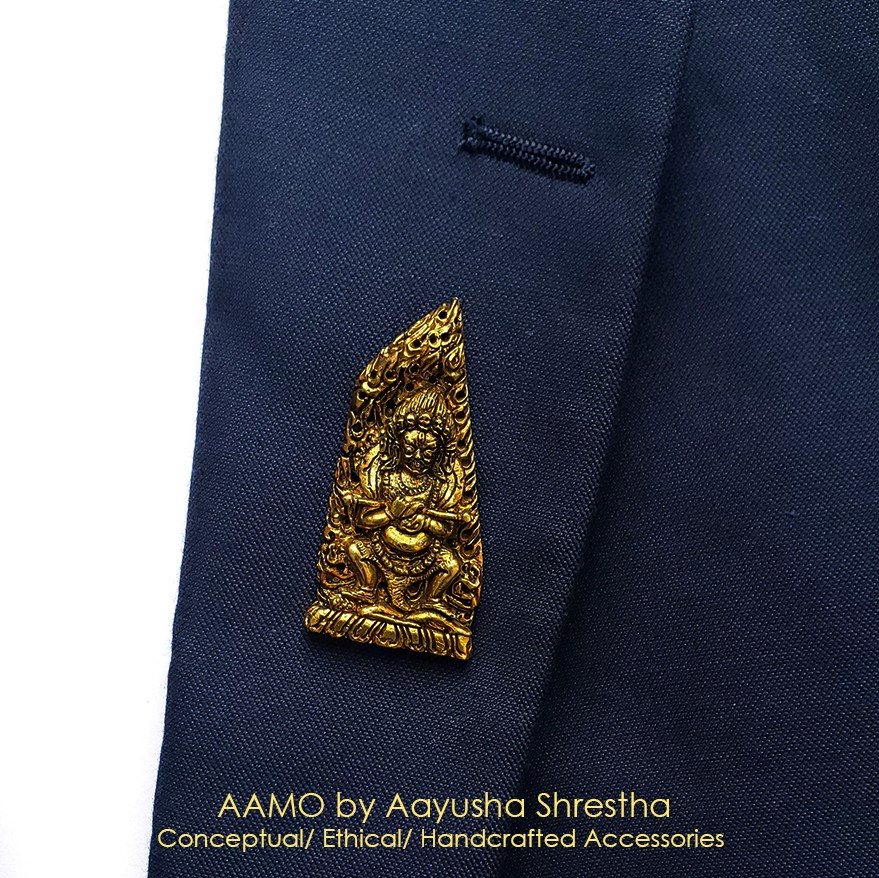

Wool and people involved in the trade have had a long and prosperous history in Nepal. The unique skills of the trans-Himalayan trade and of the processing and manufacture of wool have been passed down in some families over many generations. Apart from being a major source of woolens for tourists and exporters to markets abroad, and providing employment to large numbers of people through numerous factories and cottage industries, the wool merchants of Nepal play yet another important role, promoting handmade woolens as a regional art form. The Tuladhars, for example, are proud of their family’s part in this history, and in the maintenance and preservation of woolens as art.

To contact the wool merchants at the Tuladhar store Thamel, phone 423.1314